CNC Certification:Better Job Opportunities& Higher Earning Potentialin Just 8 Weeks!

APPLY TODAY

NEWS

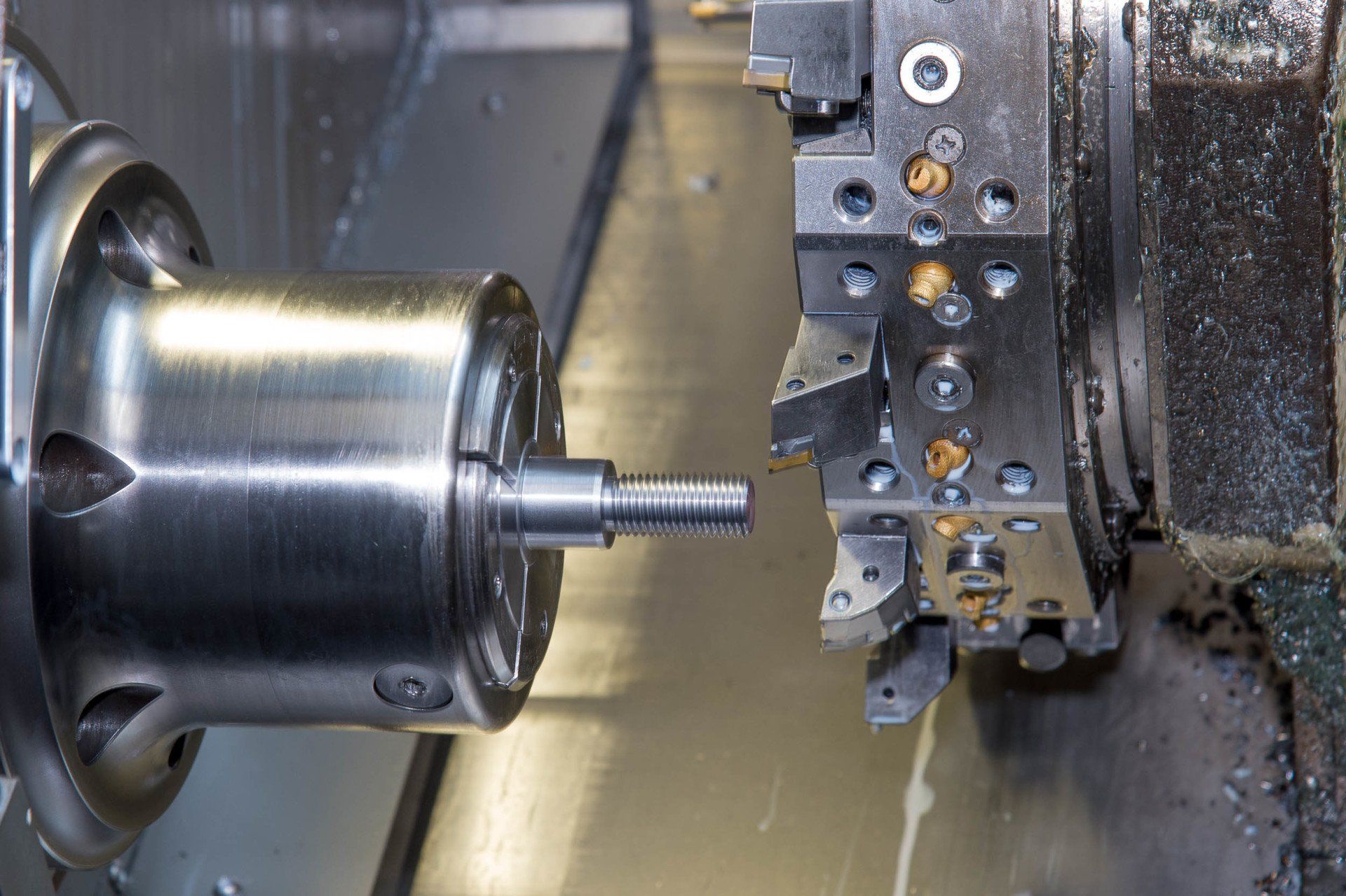

Qualify for a competitive career in CNC Milling and Turning

The ongoing transition to Computer-Numerical-Controlled equipment has created a real demand for highly trained, certified CNC Machinists. Epic CNC Training Academy will prepare you with the job-ready machining skills employers are looking to hire.

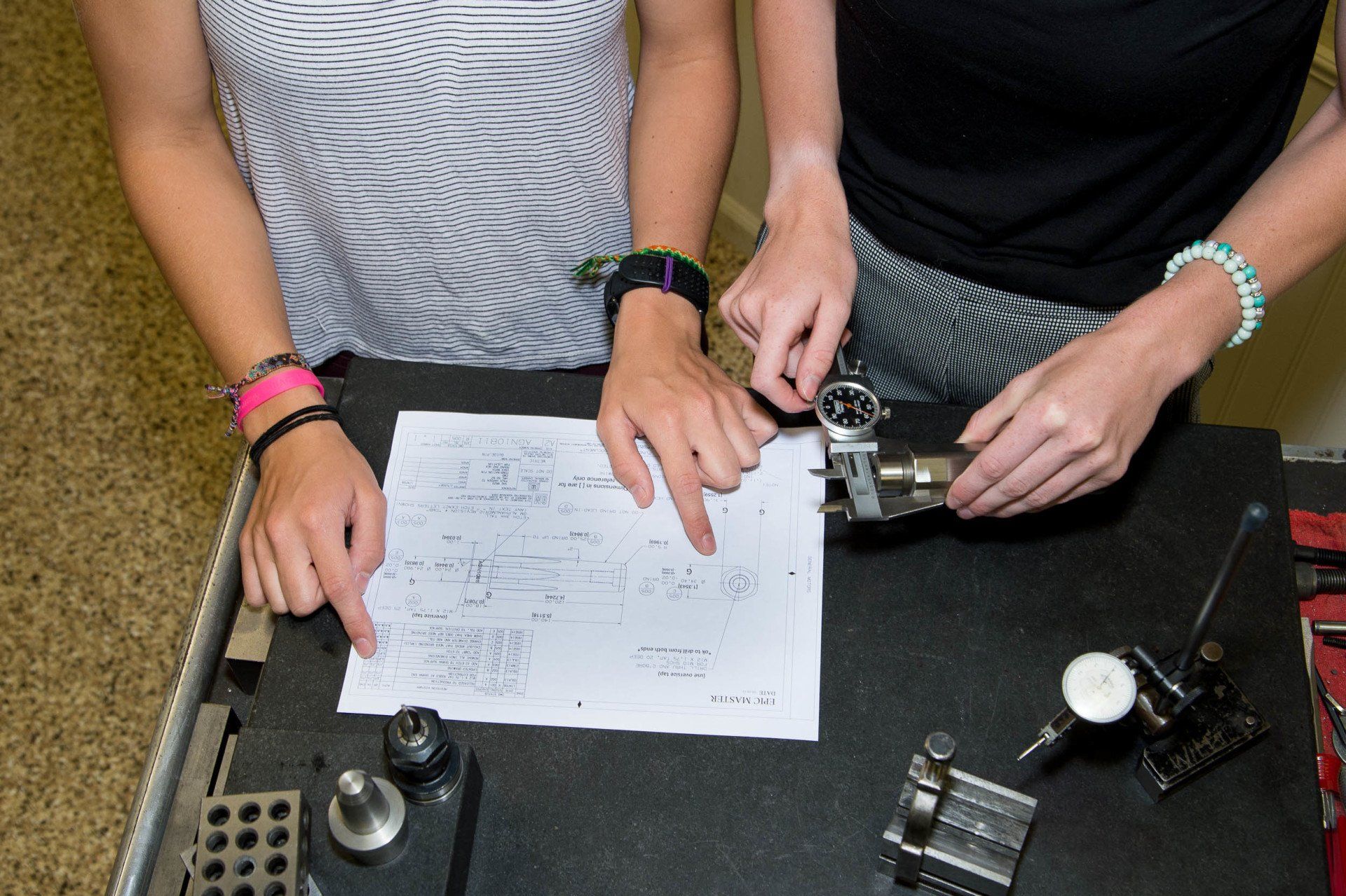

- 8 Weeks - 40 hours per week

- Limited space to ensure one-on-one training

- Use professional CNC equipment

- Ask about financing options

- Instructors are professional CNC machinists

- and programmers

- Must be 18 years or older

Epic CNC Training Academy is accepting applications now!

About CNC

How can CNC training benefit you?

The ongoing transition to Computer-Numerical-Controlled equipment has created a real demand for highly trained, certified CNC Machinists. Epic CNC Training Academy will prepare you with the job-ready machining skills employers are looking to hire.

Apply Online or by mail today. Contact us for further details.

Epic CNC Training Academy is accepting applications now!

News

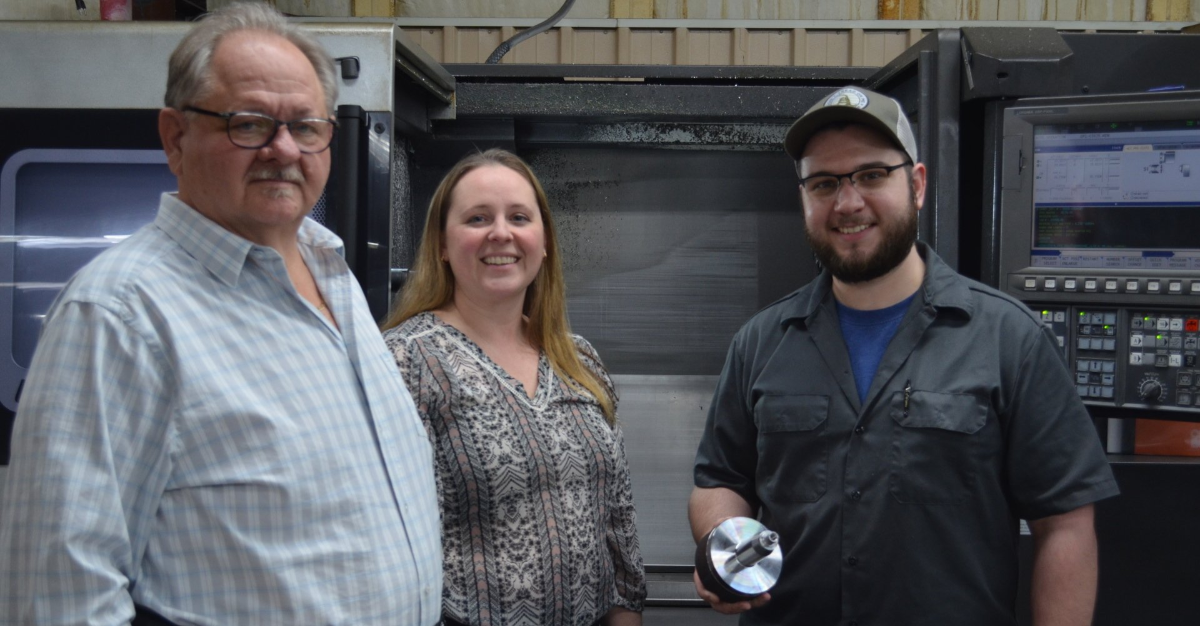

Most people don’t see manufacturing for the rich and complex industry it is. They hear the word “manufacturing” and they think first of the global giants; the companies that employ thousands of people and make exciting end products — the household brands. But for every large corporation, hundreds of small manufacturers dot the landscape of Michigan. These businesses do what they do each day with little fanfare or recognition. Based in Fenton, Epic Machine, Inc. is one such manufacturer; quietly celebrating 40 years as a manufacturer of replacement components and tooling for the foundry industry, with a diverse base of more than 200 customers. They are in the shadows of an industry sector that itself is in the background. Epic Machine is multiple degrees of separation away from public notoriety; yet they are thriving, growing and innovating. “Most people don’t know we’re here and trying to explain who we are and what we do can be difficult,” said Bill Johnston, comptroller for Epic Machine. “Downtime can destroy a business. If your production is offline for a weekend, a day, even a couple of hours, it can mean the difference between hitting your goals and keeping a customer or missing your goals and seeing them go to your competition.” Even while playing such an important role, manufacturing is itself forcing companies like Epic to change and reimagine where they fit in an increasingly high-tech, high-demand and global industry. “You have to diversify. It’s not even a question anymore. Things are moving too fast and there are fewer and fewer businesses that do what we do,” explained Johnston. “At some point, we’ll face another bump in the economy — you really need to have a fallback against one major customer or industry having a problem and your business being a victim of it. You have to open yourself up to doing more than you thought you could.” At Epic, they’ve worked to be more openminded about the possibilities for growth that are out there. They seek out existing businesses and take on projects that could push them outside their comfort zone. “It’s important that you take a shot at doing something new. Small businesses can disappear because of one or two bad quarters, so if you aren’t trying something because it’s unfamiliar, you are leaving yourself open to a lot of risk,” Johnston said. “You don’t need to take on every new client, but make expanding your knowledge base and your customer base a priority. It can add decades to your business.” Johnston and his team continue to look ahead to the company’s next milestone — their 50-year anniversary. To get there, they’ll continue with diversification strategies and move forward with plans to bring in new, tech-savvy talent and invest in new technology and upgraded equipment. Change is inevitable for manufacturers and the small business needs to advance even faster. “We may not be the biggest company but we have four decades of history behind us and you’d be surprised how reliant our world is on having small parts and replacement parts on hand when they are needed,” said Johnston. “Epic Machine is a hard-working business, founded in humility and making a quality part. Come and get to know us.”

On any given day inside Epic Machine’s high-tech manufacturing facility, Pete Jamieson has his hands full making high-precision machined parts that are shipped to customers in 29 states and 12 countries for use in everyday products. He and his colleagues produce the rollers used in production of Kellogg’s Frosted Mini-Wheats cereal. Ever drink from a McDonald’s cup? Epic makes vacuum molds that generate the 5 million lids for McDonald’s beverages sold annually. Their handcrafted expertise is also used in products for General Motors, Ford, Chrysler, Mercury Marine, John Deere, Navistar, Briggs & Stratton and more than 200 other customers that make products ranging from medical equipment and solar energy parts to tooling components for fire hydrants and manhole covers. It’s a labor of love, Jamieson said. “I’ve been here three years and it’s just awesome – I have a great career,” said the Byron native, whose twin brother, Tom, works alongside him at Epic Machine’s nondescript, 38,000-square-foot factory just east of U.S. 23 between Ann Arbor and Flint in southern Genesee County.