810-629-9400 |

epic@epiccncacademy.com

Syllabus

Syllabus

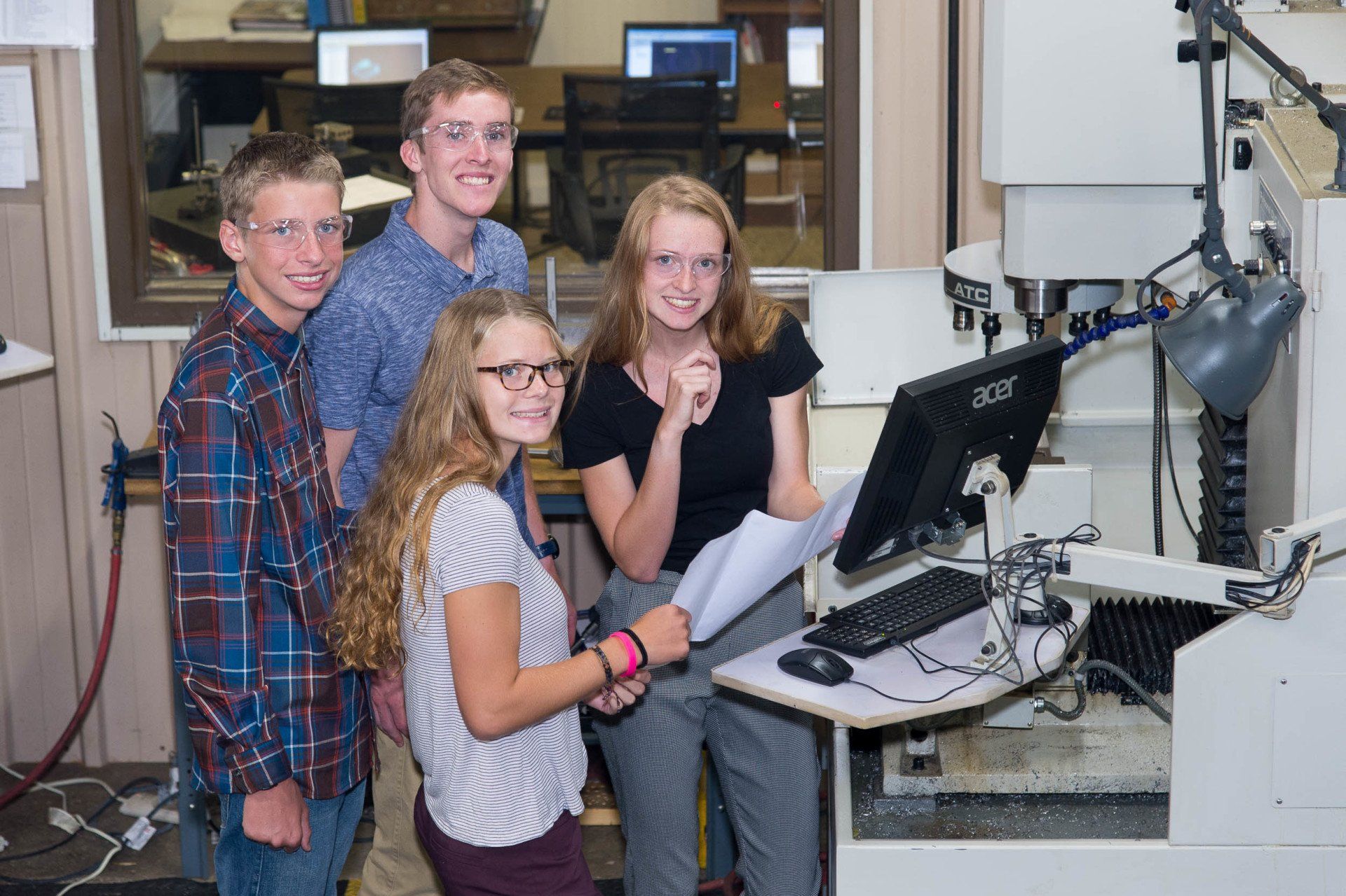

Introduction to Manufacturing

An overview of machine shop safety, proper industry language & terminology.

Technical Math & Blueprint Reading

Specific Geometry and Trigonometry formulas used in everyday machining, identifying tolerances, revision levels, & GT&D on industry standard blueprints.

Measuring Equipment

Introducing students to industry standard equipment used to accurately measure manufactured components. Hands on experience with a variety of measuring instruments including micrometers, calipers, indicators and height gages.

Intro to Machining

Learning about the variety of materials used in manufacturing along with the tools used to machine it. Exposure to proper speeds and feeds of the machine thru hands-on training with manual machining equipment.

CNC Programming

Understanding G&M code programming in order to both modify existing programs as well as manually long-hand program directly into the machine.

Machining Phase I

Learning the first steps to machining actual product. How to hold the material properly, indicating in the work piece, basic operation of the machine, and tooling off sets.

Cad/Cam & Post Processing

Exposure to 2D programming, computer simulations of machine tool paths and post-processing to CNC equipment.

Machining Phase II

Running through the whole process start to finish. Manufacturing parts of various size, material type and level of difficulty.

Supplies and Equipment

Each student will be assigned to a professional CNC machine and receive a toolbox of standard equipment and a copy of the Machinist Handbook.

© 2024

All Rights Reserved | Website Design by Behind Your Design